3D Printing and Engineering

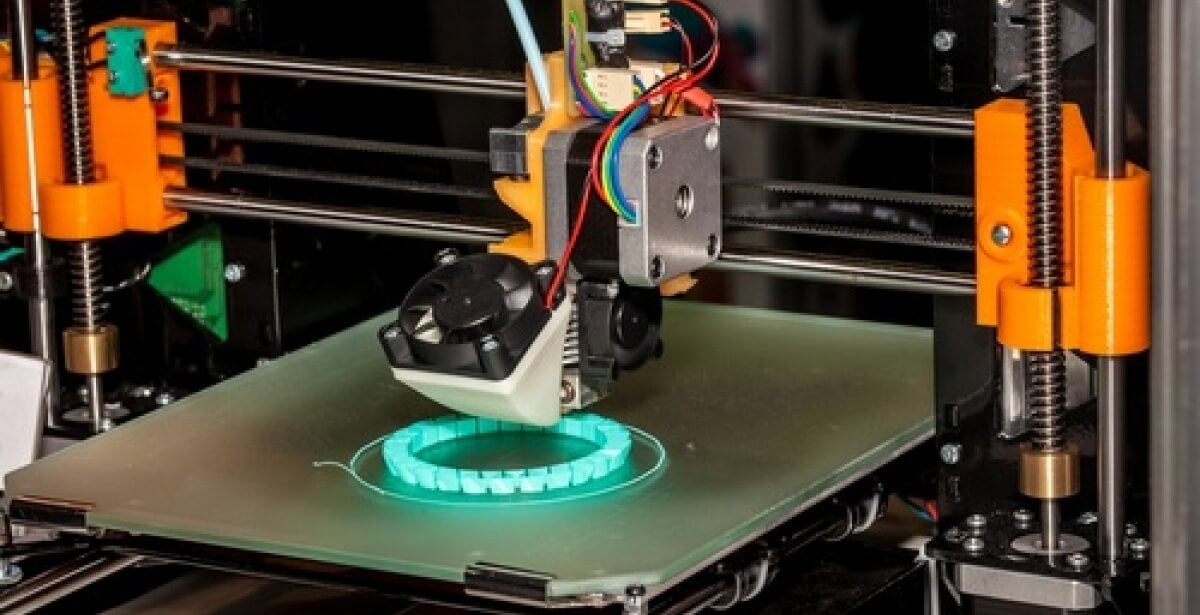

From cars to phones to prosthetics, 3D printers (3DP) are helping to solve manufacturing challenges. Companies around the globe are using 3DP technology to create prototypes and customized products. This technology is changing how mechanical engineers work, how they are educated, and how they implement lean manufacturing.

The Rise of the 3D PrinterCost is one of the driving factors for the increase in 3D printer use. The printers have become more affordable, dropping from early prices of $20,000 to just $400 for a current desktop model. The printers are delivering significant cost savings for businesses. Businesses save time and money printing plastic prototypes instead of manufacturing full-scale models out of the same materials used for final products. Thanks to 3D printers, you can print a plastic or metal prototype during a planning meeting, thereby providing an opportunity to visualize the item you are discussing in real time.

More than two-thirds of U.S. manufacturing companies are using 3DP, according to PricewaterhouseCoopers. According to a survey by PWC, 51% of U.S. manufacturers are using 3D printing for prototyping and final products. That’s an increase from 35% two years ago. The survey points out that 3D printer use is expected to continue to grow. Fifty-two percent of manufacturers say they plan to use it for high-volume production in the next 3 to 5 years.

Engineers are innovating how they use 3DP every day. After the Flint, MI, lead-water crisis, two students from Kettering University used a 3D printer to create an adaptable water filter to fit over home water faucets. Ford is testing 3DP auto-parts for more customization in its vehicles. Google is printing phones with personalized features. NASA is working on printable food for astronauts. Biomedical engineers are working on 3DP for prosthetics, cosmetic surgery, and even organ transplants.

3DP and Lean Manufacturing3DP allows engineers to be more agile and create customized parts quickly. They can spend more time making parts, instead of tinkering. The implications are shorter lead times, faster development, faster testing, and quick creation of parts. 3DP has the potential to reduce all 7 types of waste in a lean production system. It cuts down on overproduction, waiting, transporting, processing, inventory, excess motion, and defects. The use of 3D printing has a significant impact on supply chains that used to be involved in the prototype process. With prototypes now printed on site, companies now require more materials to feed printers. To stay relevant, supply chains are challenged to re-think the types of parts required and how 3D printing impacts the supply chain.

3DP, Engineers, and StudentsToday, mechanical engineers and engineering students not only need to have 3DP skills, they need to keep innovating considering new uses and applications for 3DP.. For example, the short history of 3DP, the printers have used layers of either plastic or metal to create a product. This created an issue with plastic waste and storage. Now, engineers are using plant-based products such as cellulose for a “greener” printed product. Organic and bio-compatible materials such as patient stem-cells are being tested for possible medical use. As 3DP continues to evolve, composite materials are being tested for new weather-resistant building technology.

As 3DP becomes the go-to technology replacing traditional manufacturing methods, a degree in mechanical engineering needs to consider how these new technologies impact what is currently part of the curriculum and how that curriculum may need to evolve to keep up with innovations in the field. As a disruptive technology 3DP is only one example of how the field of engineering and engineering education continues to evolve.

Kettering Online's Innovative Master's Degree in ECE

In the MS Engineering-ECE-Advanced Mobility program, engineers learn and practice cutting-edge applications for electric, hybrid, autonomous vehicles, and transportation systems. The program challenges students to work and design in a Simulink lab developing solutions for dynamic systems, controls, and digital signal processing. They also learn to design dynamic systems which enhance and support autonomous functionality, and robotics enhanced by artificial intelligence. Courses challenge engineers to develop the next level of safety, efficiency, and infotainment systems while considering the input of human driver behavior. Students graduate ready to contribute to the future development of electric and autonomous vehicles, mobile robotics and other dynamic systems.